- 3D打印 增材制造视频

- Creo Pro/ENGINEER视频

- Creo 2.0高级建模系列视频教程

- Siemens NX视频

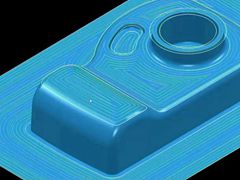

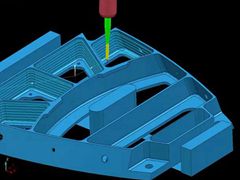

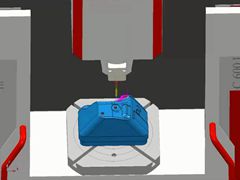

- NX CAM视频

- SolidEdge视频

- SolidWorks视频

- Moldex3D视频

- CATIA视频

- 中望3D视频

- Autodesk视频

- Delcam视频

- hyperMILL视频

- Cimatron视频

- MasterCAM视频

- 3D扫描 3D测量视频

- Geomagic逆向视频

- Creaform视频

- 模具及成型视频

- 注塑及注塑机视频

- 综合视频

- 其他CAD设计视频

- 其他CAM加工视频

- Freeform触觉式设计视频

- Tebis视频

- KeyShot渲染视频

- 机床加工视频

- Creo 2.0高级建模系列全套视频教程

- Creo 2.0零件设计视频教程

- SolidWorks 2014 基础教程视频

- SolidWorks 2014 实用教程视频

- CATIA IMA 曲面设计视频教程

- NX8.5 模具设计视频教程

- NX9.0 曲面补面高级技巧与应用

- NX10.0 编程加工基础与应用视频教程

- NX10.0 基础建模全套视频教程

收藏

收藏 淘帖

淘帖 顶一下

顶一下